Science

MIT Launches Advanced Manufacturing Education Program Nationwide

The Massachusetts Institute of Technology (MIT) has introduced a new initiative designed to enhance the skills of the U.S. manufacturing workforce. The program, named the Technologist Advanced Manufacturing Program (TechAMP), aims to bridge the skills gap between traditional roles within the industry and emerging needs. Funded by the U.S. Department of Defense, this innovative educational effort combines in-person lab instruction, online lectures from MIT faculty, and interactive simulations, providing participants with a comprehensive understanding of modern manufacturing practices.

New Pathways for Workers

TechAMP is structured as a 12-month certificate program that provides training in core manufacturing principles, empowering employees and companies alike. Participants will engage in capstone projects that tackle real-world manufacturing issues, with the goal of delivering substantial savings to their firms. The program is designed to formalize the concept of the accredited “technologist,” which is seen as a vital role in the manufacturing sector.

“We think there’s a gap between the traditional worker categories of engineer and technician, and this technologist training fills it,” stated John Liu, a principal research scientist in MIT’s Department of Mechanical Engineering and co-principal investigator of TechAMP. Liu emphasized that the program offers new career pathways, encouraging workers to adopt a holistic view of manufacturing operations rather than focusing solely on individual tasks.

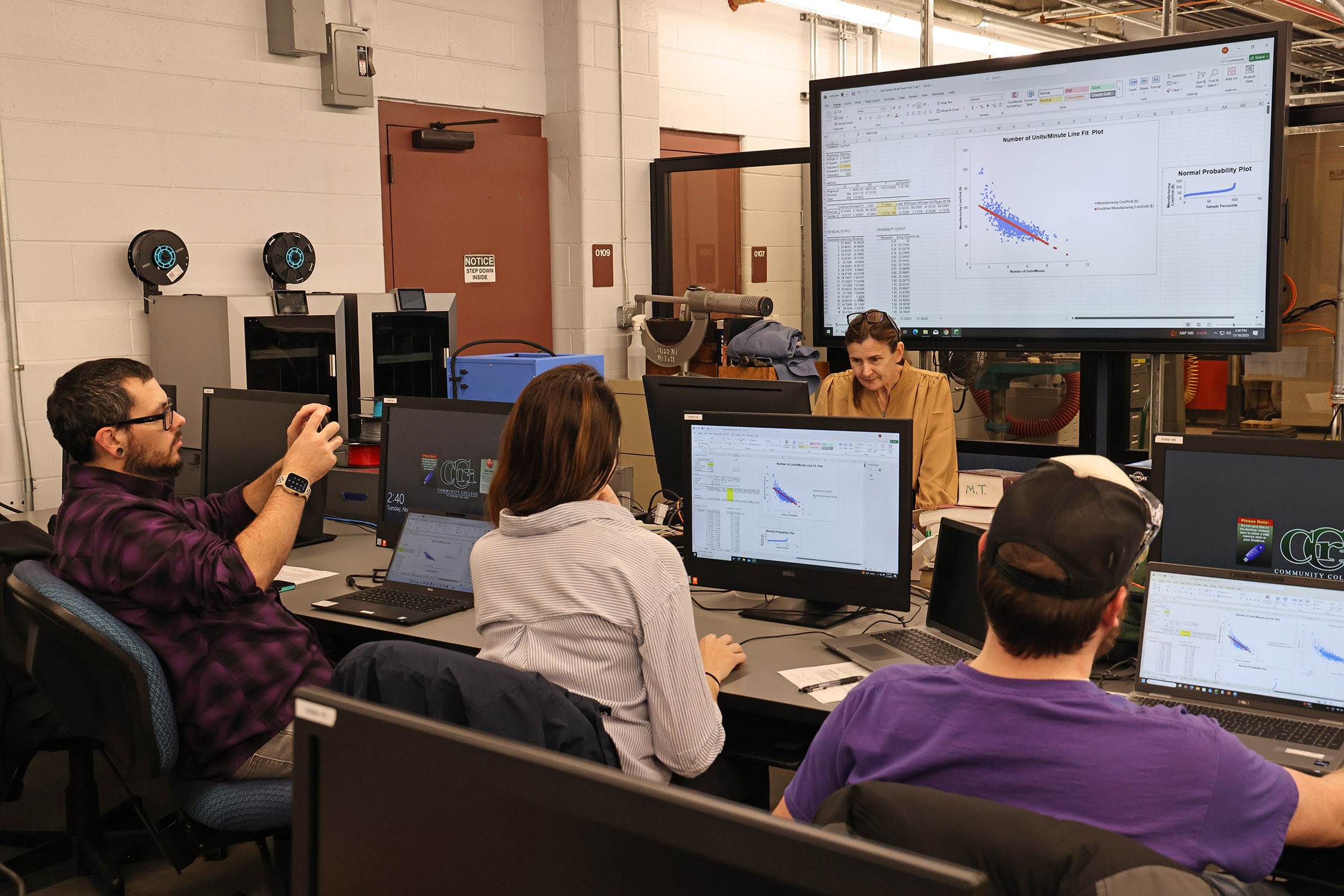

Launched this fall, TechAMP has partnered with several institutions, including the University of Massachusetts at Lowell, Cape Cod Community College, Ohio State University, and the Community College of Rhode Island. The initial cohort comprises over 70 students who are eager to develop their skills in a rapidly evolving industry.

Responding to Industry Needs

The initiative forms part of MIT’s broader Initiative for New Manufacturing (INM), which seeks to rejuvenate manufacturing in the United States. Launched in May 2025, the INM is focused on fostering innovative approaches in partnership with various industry firms. “Through TechAMP and other programs, we’re excited to reach beyond MIT’s traditional realm of manufacturing education and collaborate with companies of all sizes,” said John Hart, head of the Department of Mechanical Engineering at MIT.

The curriculum is built around a “hub-and-spoke” model, featuring core manufacturing concepts—such as process controls, manufacturing systems, leadership skills, and operations management—alongside six specialized areas identified through collaboration with industry partners. These areas currently include mechatronics, automation programming, robotics, machining, digital manufacturing, and design fundamentals, although they may evolve based on industry feedback.

“The hub concepts are what defines manufacturing,” Liu explained. “We need to teach this undervalued set of principles to the workforce, including people without university degrees.” The aim is to equip workers with a timeless understanding of manufacturing, allowing them to adapt to various industrial contexts.

Participants in the program report a positive impact on their confidence and career outlook. Nicole Swan, a student from Proterial, expressed that the program has opened her eyes to numerous future opportunities, enhancing her sense of self-worth and aspirations.

Potential for Direct Value Creation

The TechAMP program’s capstone project encourages students to analyze challenges within their firms, potentially leading to cost savings or increased value. If successful, this could incentivize employers to invest in their employees’ participation in TechAMP, which requires a commitment of approximately 10 to 14 hours per week over the course of a year.

Michael Trotta, CEO of Crystal Engineering, noted the importance of high-skill roles that do not necessarily require a four-year degree. He views TechAMP as a crucial step in developing a sustainable manufacturing workforce. Trotta and his employees actively contributed to shaping the TechAMP curriculum, ensuring its relevance to industry needs. “We want workers to progress to positions where they can earn significantly more, thanks to their expanded skill sets,” he explained.

As the recognition of the technologist role grows within the manufacturing sector, MIT’s approach is seen as a transformative solution. Drawing a parallel to the nursing profession, Diop remarked, “The role of nurse practitioner bridges the gap between nurse and doctor. Manufacturing has had a reputation for dead-end jobs, but if MIT can help break that image by providing a real pathway, that would be meaningful.”

Research indicates that a significant portion of engineers in manufacturing do not hold formal engineering degrees, further highlighting the need for structured training programs such as TechAMP. As the program evolves, MIT leaders are exploring partnerships with additional educational networks in manufacturing-centric states, reflecting a strong demand for innovative educational solutions.

With TechAMP now underway, MIT is poised to make a lasting impact on the U.S. manufacturing landscape, fostering a new generation of skilled technologists ready to tackle the challenges of modern industry.

-

Technology5 months ago

Technology5 months agoDiscover the Top 10 Calorie Counting Apps of 2025

-

Health3 months ago

Health3 months agoBella Hadid Shares Health Update After Treatment for Lyme Disease

-

Technology1 week ago

Technology1 week agoOpenAI to Implement Age Verification for ChatGPT by December 2025

-

Health3 months ago

Health3 months agoErin Bates Shares Recovery Update Following Sepsis Complications

-

Technology4 months ago

Technology4 months agoDiscover How to Reverse Image Search Using ChatGPT Effortlessly

-

Technology3 months ago

Technology3 months agoElectric Moto Influencer Surronster Arrested in Tijuana

-

Technology1 month ago

Technology1 month agoDiscover 2025’s Top GPUs for Exceptional 4K Gaming Performance

-

Health3 months ago

Health3 months agoAnalysts Project Stronger Growth for Apple’s iPhone 17 Lineup

-

Technology5 months ago

Technology5 months agoMeta Initiates $60B AI Data Center Expansion, Starting in Ohio

-

Technology5 months ago

Technology5 months agoRecovering a Suspended TikTok Account: A Step-by-Step Guide

-

Health5 months ago

Health5 months agoTested: Rab Firewall Mountain Jacket Survives Harsh Conditions

-

Lifestyle5 months ago

Lifestyle5 months agoBelton Family Reunites After Daughter Survives Hill Country Floods