Science

Beihang University Develops Innovative Robot for Aircraft Wing Maintenance

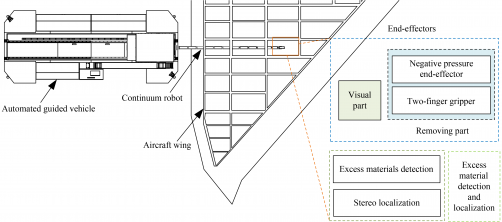

During the assembly of aircraft, excess materials such as nuts, rivets, and aluminum shavings often remain trapped within the wings. These remnants pose a significant risk, potentially disrupting the operation of critical aircraft components and leading to serious flight incidents. To address this pressing issue, researchers at Beihang University have introduced a novel solution in their study titled “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors.”

The study focuses on enhancing the efficiency of removing excess materials, which has traditionally relied on manual operations. The confined spaces within aircraft wings make manual access challenging, and conventional robotic systems often fail to navigate such narrow environments effectively. This has resulted in low efficiency during removal tasks.

The researchers employed a continuum robot equipped with a specialized removal end-effector and a stereo camera. They began by analyzing the size and weight characteristics of the materials commonly found in aircraft wings. Based on this analysis, they designed a unique negative pressure end-effector capable of removing small items like nuts and rivets, as well as a two-finger gripper intended for extracting larger volumes of aluminum shavings.

To tackle the inadequate lighting conditions often present inside aircraft wings, the team incorporated supplementary lighting devices. This enhancement is crucial for accurate detection and removal operations. For object classification and detection, the You Only Look Once (YOLO) v5 algorithm was utilized, along with the creation of two training datasets tailored for different types of wings.

Given the limited texture features within the aircraft wings, the researchers implemented an image-matching technique that leverages the YOLO v5 detection results. This method circumvents the performance instability commonly associated with traditional feature point matching systems. Experimental results demonstrated impressive outcomes, with detection accuracy for each type of excess material exceeding 90%. Additionally, the visual localization error was maintained at under 2 mm for four distinct types of excess objects.

The efficacy of the two end-effectors was confirmed through experimental verification, showcasing their capability to effectively remove excess materials from aircraft wings. The research paper, authored by Xiujie Cao, Jingjun Yu, Siqi Tang, Junhao Sui, and Xu Pei, presents a significant advancement in aircraft maintenance technology.

For those interested, the full text of the paper is available at: https://doi.org/10.1007/s11465-024-0806-2. This innovative approach not only enhances the safety and reliability of aircraft operations but also showcases the potential of robotics in the aerospace industry.

-

Science2 weeks ago

Science2 weeks agoNostradamus’ 2026 Predictions: Star Death and Dark Events Loom

-

Technology1 month ago

Technology1 month agoOpenAI to Implement Age Verification for ChatGPT by December 2025

-

Technology6 months ago

Technology6 months agoDiscover the Top 10 Calorie Counting Apps of 2025

-

Health4 months ago

Health4 months agoBella Hadid Shares Health Update After Treatment for Lyme Disease

-

Health4 months ago

Health4 months agoAnalysts Project Stronger Growth for Apple’s iPhone 17 Lineup

-

Health4 months ago

Health4 months agoErin Bates Shares Recovery Update Following Sepsis Complications

-

Technology4 months ago

Technology4 months agoElectric Moto Influencer Surronster Arrested in Tijuana

-

Technology5 months ago

Technology5 months agoDiscover How to Reverse Image Search Using ChatGPT Effortlessly

-

Technology6 months ago

Technology6 months agoMeta Initiates $60B AI Data Center Expansion, Starting in Ohio

-

Technology6 months ago

Technology6 months agoRecovering a Suspended TikTok Account: A Step-by-Step Guide

-

Education4 months ago

Education4 months agoHarvard Secures Court Victory Over Federal Funding Cuts

-

Technology2 months ago

Technology2 months agoDiscover 2025’s Top GPUs for Exceptional 4K Gaming Performance