Technology

Six Technologies Revolutionizing Electronics Manufacturing Today

The electronics manufacturing sector is undergoing a significant transformation driven by advancements in technology. As of now, approximately **90%** of manufacturers have integrated some form of **artificial intelligence** into their operations. This shift coincides with a growing need for automation, particularly as the industry grapples with a labor shortage estimated to leave **500,000 to 600,000 positions** unfilled. The smart factory software market is projected to reach **$97 billion** by **2028**, indicating the urgent necessity for modern solutions that enhance efficiency and productivity.

As manufacturers adapt to these challenges, six key technologies are emerging as pivotal in reshaping production processes. This article delves into how these innovations are streamlining electronics manufacturing and redefining industry standards.

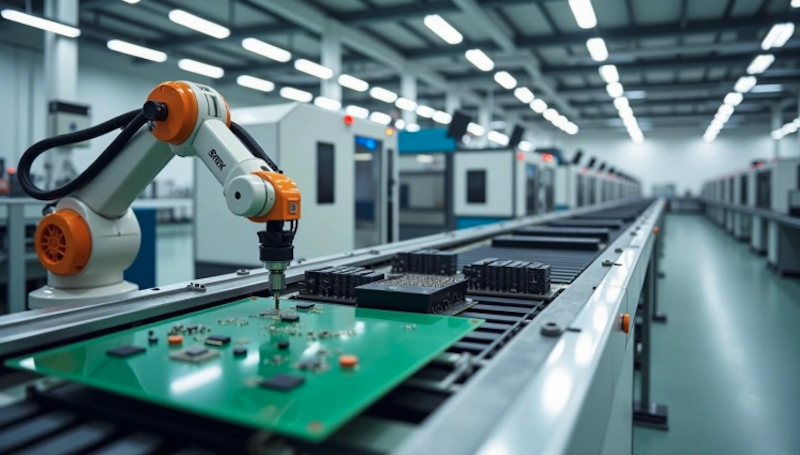

Automation and Robotics

Robotic systems are increasingly becoming integral to electronics manufacturing. The sector accounted for **28%** of all new robot installations in **2022**, with over **103,000** units deployed for various applications. These robots excel at executing intricate, high-precision tasks that were once deemed impossible to automate. Equipped with advanced computer vision, modern machines can achieve an accuracy of **±0.04 millimeters** when placing microscopic components, significantly reducing errors and enhancing product quality.

Collaborative robots, or **cobots**, are also gaining traction. One factory reported a **25%** increase in assembly line speed following their introduction, showcasing the advantages of integrating robotics into production lines.

Artificial Intelligence and Machine Learning

The role of artificial intelligence and machine learning extends beyond traditional automation. These technologies analyze extensive data sets to identify patterns and predict outcomes, enhancing production efficiency. AI-powered vision systems can detect surface flaws, cracks, and subtle color variations that are invisible to the naked eye, thus improving product yield and minimizing waste.

One manufacturer noted a **30%** increase in efficiency and a **97%** yield by employing deep neural networks in their quality control processes. This highlights the substantial benefits AI brings to modern manufacturing.

Smart Logistics and Supply Chain Management

Smart logistics has become essential for maintaining efficiency in electronics production. Advanced tracking tools and automated warehouses now manage the flow of components between suppliers and assembly lines with exceptional precision. Real-time monitoring ensures that sensitive materials remain secure during transit, further minimizing delays and losses.

Companies like **Greenwave Electronics** are at the forefront of this innovation, offering specialized third-party logistics (3PL) solutions that help manufacturers reduce costs and streamline operations.

Internet of Things (IoT)

The **Internet of Things** (IoT) has emerged as a critical network connecting machines, people, and processes. Sensors integrated into equipment provide real-time data on performance, energy consumption, and quality control. This continuous flow of information empowers managers to make informed decisions that enhance operational efficiency and reduce waste.

The IoT enhances various aspects of production, from energy management to predictive maintenance, allowing manufacturers to optimize their processes in real time.

Advanced Printed Circuit Board Design

Advanced printed circuit board (PCB) design remains the backbone of modern electronic devices. New techniques in PCB manufacturing have significantly improved both efficiency and product quality. The implementation of Design for Manufacturing (DFM) analysis allows engineering teams to identify potential issues early in the design phase, which helps prevent costly redesigns later on.

Organizations like **ACDI** specialize in PCB design services that combine precision with innovative manufacturing practices, enabling electronics manufacturers to produce high-performance devices more efficiently.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as **3D printing**, is revolutionizing the production of electronic components. This technology enables the creation of complex, customized parts that traditional manufacturing methods struggle to achieve. By building components layer by layer, materials such as plastics, metals, and conductive inks can be utilized to fabricate intricate three-dimensional structures.

Key methods of 3D printing include fused deposition modeling (FDM) and selective laser sintering (SLS), which facilitate the rapid prototyping and production of components tailored to specific needs.

The evolution of electronics manufacturing signifies more than just technological advancements; it represents a holistic transformation in how industries approach design and production. Each innovation, from robotics to additive manufacturing, contributes to a more precise and environmentally responsible production process.

By integrating intelligent systems, manufacturers can leverage real-time data to make informed decisions, anticipate challenges, and ensure greater consistency across global operations. The future of manufacturing will not only rely on technological innovations but also on the collaboration between human expertise and machine intelligence, paving the way for a more efficient and sustainable industry.

-

Technology5 months ago

Technology5 months agoDiscover the Top 10 Calorie Counting Apps of 2025

-

Technology3 weeks ago

Technology3 weeks agoOpenAI to Implement Age Verification for ChatGPT by December 2025

-

Health3 months ago

Health3 months agoBella Hadid Shares Health Update After Treatment for Lyme Disease

-

Health3 months ago

Health3 months agoAnalysts Project Stronger Growth for Apple’s iPhone 17 Lineup

-

Health3 months ago

Health3 months agoErin Bates Shares Recovery Update Following Sepsis Complications

-

Technology5 months ago

Technology5 months agoDiscover How to Reverse Image Search Using ChatGPT Effortlessly

-

Technology3 months ago

Technology3 months agoElectric Moto Influencer Surronster Arrested in Tijuana

-

Technology2 months ago

Technology2 months agoDiscover 2025’s Top GPUs for Exceptional 4K Gaming Performance

-

Technology5 months ago

Technology5 months agoMeta Initiates $60B AI Data Center Expansion, Starting in Ohio

-

Technology5 months ago

Technology5 months agoRecovering a Suspended TikTok Account: A Step-by-Step Guide

-

Health5 months ago

Health5 months agoTested: Rab Firewall Mountain Jacket Survives Harsh Conditions

-

Lifestyle5 months ago

Lifestyle5 months agoBelton Family Reunites After Daughter Survives Hill Country Floods